Combine structural strength, architectural freedom, and environmental excellence with three prefabricated TimberROC® wood-based concrete systems. Fast installation and high industrial quality ensure full control of both schedule and costs.

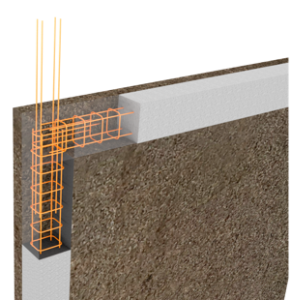

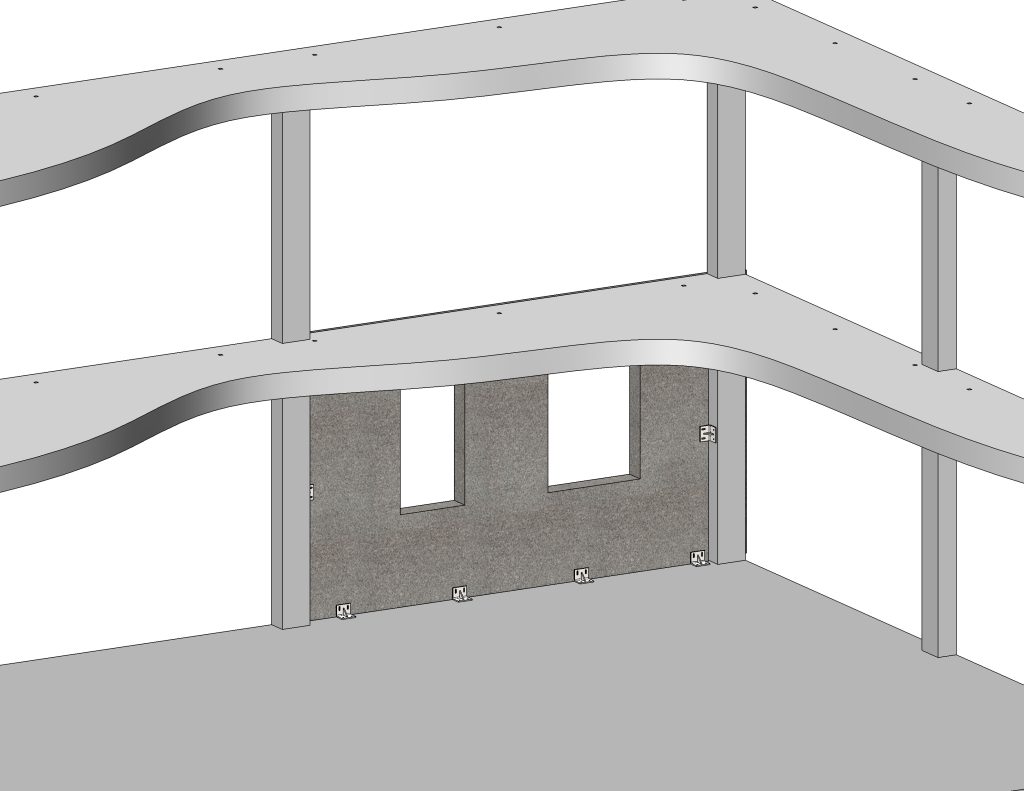

CS2 – TimberROC® load-bearing wall with integrated concrete reinforcement

As a primary structural solution, the CS2 system combines the lightness and strength of TimberROC wood-based concrete. Prefabricated panels leave the plant ready for reinforcement placement and casting of vertical and horizontal tie beams — saving time on site while ensuring full structural continuity.

With the CS2 system, you get a ready-to-use low-carbon wall that supports the structure while providing optimal hygrothermal comfort inside the building — one panel, multiple functions!

Applications

For residential, multi-family, and commercial buildings up to four storeys; vertical extensions possible.

Public buildings (categories 1 to 5), industrial or agricultural facilities up to 8 m high.

Seismic zones 1 to 4 and wind zones 1 to 4 in France.

Complies with ATEx case A n° 3044_V3 (CSTB)

Construction and operation benefits

- Fast installation: integrated lifting anchors and optimised panel layout.

- Controlled quality: licensed production under CCB Greentech supervision.

- Poly-finishing: rendering, ETICS or ventilated cladding.

- Low maintenance: rot-proof, frost-resistant, and insect-resistant material.

Key performances

Carbon footprint

From neutral to –17 kg CO₂ eq/m² (30 cm thickness, INIES EPD). RE2020 compliant up to the 2031 threshold!

Thermal time lag

14 h (24 cm) / 17 h (30 cm) – guaranteed summer comfort.

Fire resistance

Up to REI 180 min; Class A2-s1-d0.

Acoustic insulation

αw 0.70 (bare wall).

Prefabrication

300 m² installed per day; no wet work required except for reinforcements.

Dimensions and installation

| Paramètre | Valeurs standards |

|---|---|

| Longueur panneau | 0,40 m – 8,00 m |

| Hauteur utile | 0,40 m – 3,80 m |

| Épaisseur | 24 cm (standard) / 30 cm (haute inertie) |

| Masse surfacique | 192 kg/m² (24 cm) / 240 kg/m² (30 cm) |

Go further

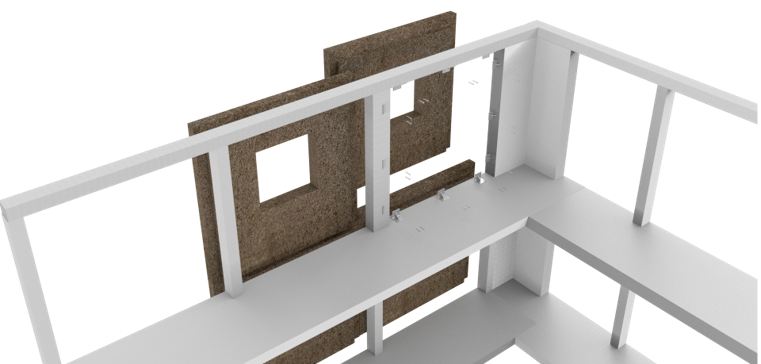

FP2 – TimberROC® self-supporting (non-load-bearing) wall panel

The FP2 system is a prefabricated wood-based concrete panel designed to be fixed onto an existing post-and-beam structure. Each panel rests on the one below, forming a continuous, biosourced façade. Ready for rendering or cladding, it is installed after the main structure is completed — without extending the project timeline.

The FP2 combines lightness, thermal performance, and fast installation — a façade that speeds up construction without compromising on carbon impact.

Applications

- Suitable for residential and multi-family buildings up to four storeys, and public-access buildings (categories 1 to 5).

- Also applicable to non-residential, industrial, or agricultural buildings up to 8 m high.

- Approved for seismic zones 1 and 2, and wind zones 1 to 4 in France.

- Compliant with CSTB ATEx Case A No. 3152_V1.

Construction and operation benefits

- Sequenced installation: fitted after concrete pouring — zero interference with the structural works.

- Industrial precision: controlled tolerances, integrated edge strips and rebates.

- Architectural flexibility: spans up to 7 m, multiple finishes.

Low-carbon performance: ready-to-use façade solution meeting RE2020 requirements up to the 2031 threshold.**

Key performances

Carbon footprint

–3,1 kg CO₂ eq/m² (16 cm) ; –7,3 kg CO₂ eq/m² (20 cm)

Summer comfort

Thermal time lag 9,1 h (16 cm) / 11,4 h (20 cm) ; thermal damping 82% / 90%

Fire resistance

Class A2-s1-d0.

Parements

Ventilated cladding, ETICS, render, or bonded cladding system

Dimensions and installation

| Paramètre | Valeurs standards* |

|---|---|

| Longueur | 0,40 m – 5,60 m (16 cm) / jusqu’à 7,00 m (20 cm) |

| Hauteur utile | 0,80 m – 3,30 m |

| Épaisseur | 16 cm ou 20 cm |

| Masse surfacique | 128 kg/m² (16 cm) / 160 kg/m² (20 cm)** |

*Larger dimensions available upon technical review.

**Theoretical density calculated at 800 kg/m³.

Go further

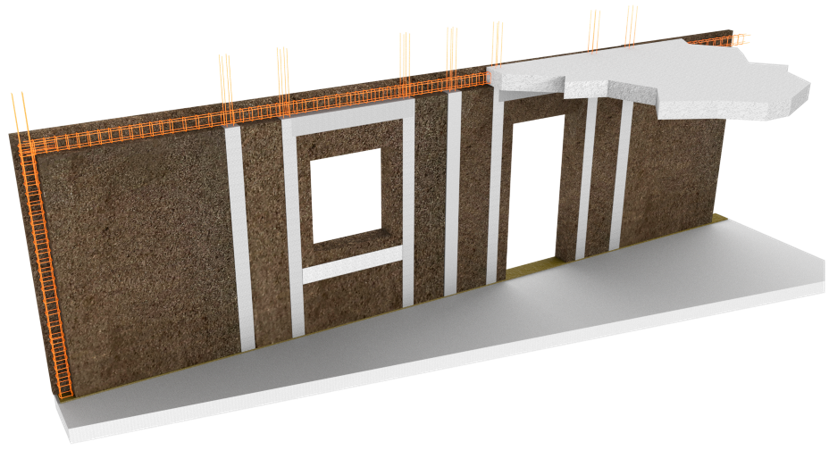

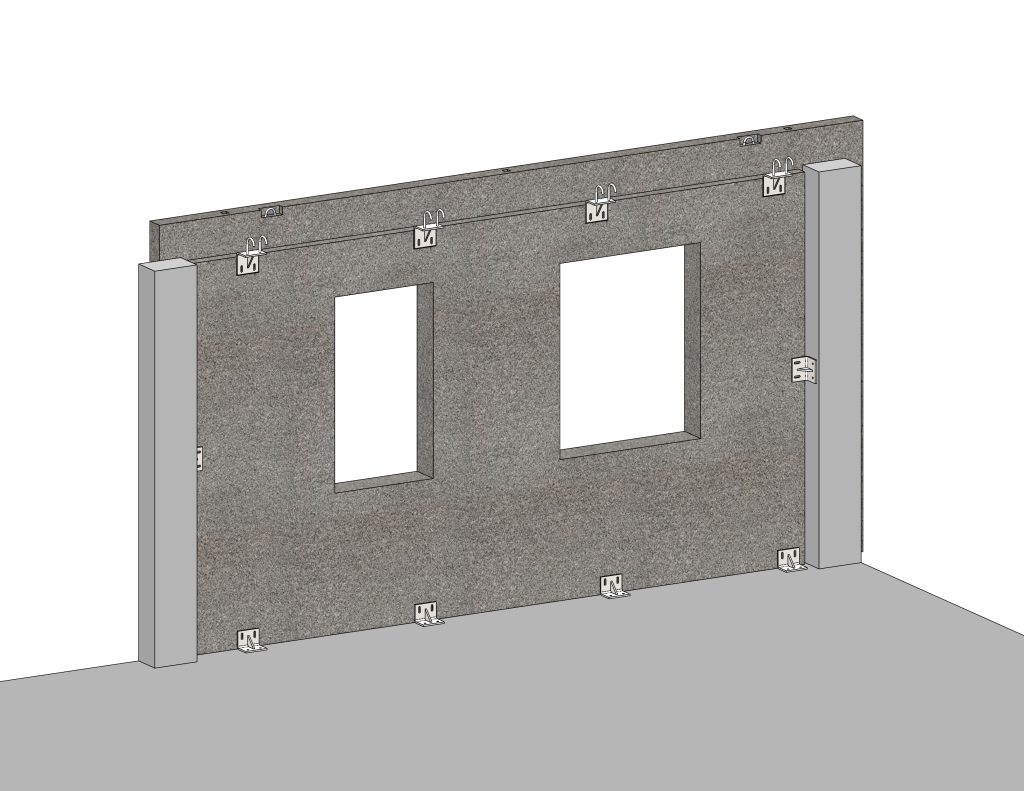

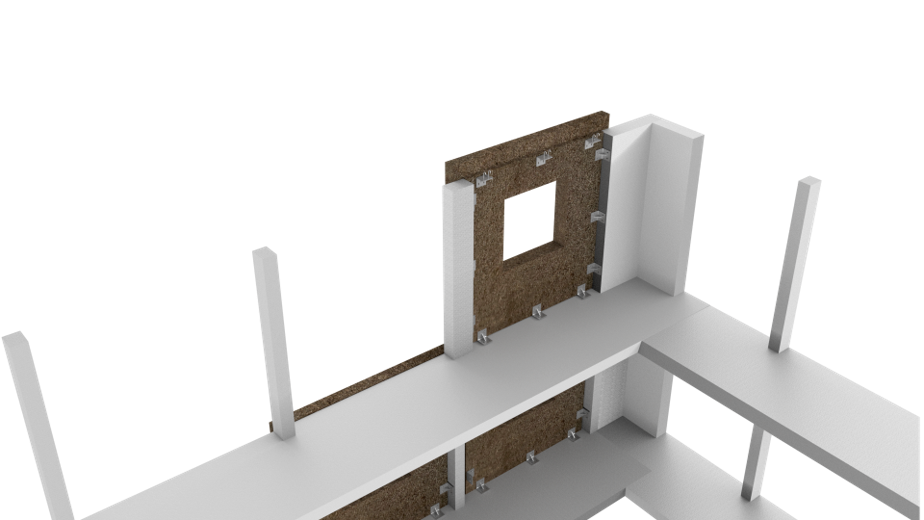

FP3 – TimberROC® façade anchored to the slab edge (non-load-bearing)

The FP3 principle uses the TimberROC® panel, but attaches it directly, level by level, to the slab nose of the concrete shell.

Used in the structural work cycle, it enables :

speed up work by secondary trades,

a clean, controlled worksite,

a high-performance carbon envelope.

The panels are prefabricated in the factory, delivered just-in-time, then secured with anchor brackets.

Applications

- Residential buildings: single-family or multi-family (types 1 to 3, categories A and B)

- Non-residential buildings

- Public-access buildings (ERP): categories 1 to 5

- Industrial or agricultural buildings: up to 8 m high

- Seismic zones 1 to 4

- Wind zone in France from 1 to 4

RE2020 project and Bâtiment biosourcé label

Conforme ATEx cas A n° 3152_V1 (mêmes règles que FP2).

Construction and operation benefits

- Implementation according to the structural work cycle

- Casting of the N+1 floor slab against the facing edge of the level N panels, with a rock wool insulation layer.

- Connection with mounting brackets

- Integrated slab and column plates

- Rockwool between panels, and between panels and concrete structure

- PU foam on both sides of each post

Key performances

Carbon footprint

–3,1 kg CO₂ eq/m² (16 cm) ; –7,3 kg CO₂ eq/m² (20 cm).

Thermal comfort

Thermal time lag 9,1 h (16 cm) / 11,4 h (20 cm) ; thermal damping ≥ 82%.

Fire resistance

A2-s1-d0 ; parement bois, enduit, bardage ventilé ou ETICS

possibles.

Mechanical resistance

wind zones 1-4, seismic zones 1-4

Dimensions and installation

| Paramètre | Valeurs standards* |

|---|---|

| Longueur | 0,40 m – 5,60 m (16 cm) / jusqu’à 7 m (20 cm) |

| Hauteur utile | 0,80 m – 3,30 m |

| Épaisseur | 16 cm ou 20 cm (module isolé) |

| Masse surfacique | 128 kg/m² (16 cm) / 160 kg/m² (20 cm) |

| Ancrages | Platines + chevilles béton ou tirefonds acier ; réglage 3D |

*Non-standard sizes available upon request.

Go further

Do you have a project ?

Contact us and we’ll get back to you as soon as possible.