Carbon footprint

How can TimberRoc® wood-based concrete, even if it is a biobased material, benefit from a negative carbon footprint?

This is negative because the quantity of CO2 stored in the wood during its growth is greater than the quantity of CO2 emitted during the other stages of the life cycle.

Negative accounting of the CO2 stored in wood during its growth is only possible, according to the standardized methodology, if the wood comes from a sustainably managed forest, i.e. one whose renewal has been verified.

We work mainly with PEFC-certified operators to ensure this sustainable management.

Has a third-party organization validated that TimberRoc® wood-based concrete has a negative carbon footprint?

There is a standardized methodology for assessing the environmental impact of a product over its life cycle, taking into account several impact criteria and all stages of the life cycle (extraction of raw materials, transport, manufacture, use, end of life, etc.).

In the building industry, this takes the form of an FDES (Fiche de Déclaration Environnementale et Sanitaire - Environmental and Health Declaration Sheet), which is also a standard-based procedure, but not mandatory.

We have had our own verified by an accredited auditor, enabling them to be officially published on the government's INIES website, which lists all verified ESDSs.

Production

What is your production capacity?

Our prefabrication partners have dedicated wood-based concrete plants with an annual capacity of over 600,000 m²/year of walls and floors in France.

Where do you produce TimberRoc® wood-based concrete?

For the time being, wood-based concrete is produced exclusively in mainland France, by our licensed prefabrication partners: Spurgin Leonhart, R-Technologies and Capremib.

Spurgin Leonhart prefabricates our different construction principles at its plants in La Roque-d'Antheron (13) and Mignières (28).

R-Technologies' production site is located in Viry (74).

Since June 2025, Capremib has also been prefabricating our construction principles in Reims (51).

Acoustics

Since wood-based concrete has a lower density than conventional concrete, what about between-level acoustics for slabs?

With DS1 floors, the presence of a traditional concrete compression slab improves acoustic performance.

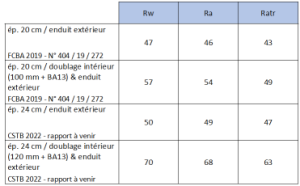

The acoustic performance of our DS1 floor system (tested by the CSTB) is given below for a configuration without suspended ceiling or floor covering (airborne attenuation index and impact noise level).

What about façade acoustics?

Here are the results of tests carried out with FCBA and CSTB.

The wood

What wood do you use to make TIMBERROC® wood-based concrete?

We supply pulpwood mainly from thinning, improvement and coppicing cuts, all of which have the particularity of harvesting small-volume trees.

These cuts are not classified as "timber". Pulpwood comes in the form of small-diameter, non-linear logs, and is mainly intended for the production of paper pulp and wood energy.

What do you do with wood waste during production? Do you recycle it?

We use all the pulpwood we supply, so 100% of the wood is recycled.

Where does the wood used to make TimberRoc® wood-based concrete come from?

The wood comes exclusively from French forests, and as such has the Bois de France label.

We source most of our wood from PEFC-certified foresters, i.e. those committed to sustainable forest management.

Faced with the current problem of wood breakage, will you have enough raw materials to make wood-based concrete in the next ten years?

Fast-growing demand on the wood market is mainly due to the timber construction sector, and therefore mainly concerns lumber.

As our wood supply for TimberRoc wood-based concrete is pulpwood, we are much less affected.

What does "additive wood" processing involve?

This is simply the addition of a non-chemical additive that optimizes the bond between cement and wood aggregate. The FDES of the wood aggregate certifies that there are no health concerns.

There are no VOC emissions (A+ label).

Construction principles

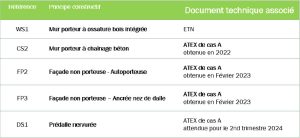

What construction principles can be envisaged? Are they certified, or will they be shortly?

Have you carried out any test projects?

Since 2006, more than sixty projects have been completed in France and fifteen in Italy, and feedback from users is unanimous on the thermal performance of wood-based concrete walls:

significant energy savings are achieved, and summer comfort and acoustic quality are remarkable.

With regard to the resistance of your timberroc® wood-based concrete load-bearing walls and their use in seismic zones, do you have any evidence to justify this in terms of the Eurocodes?

As part of our technical approval process with the CSTB, we have carried out numerous mechanical tests on a material scale and on the scale of structural elements (3-meter-high walls), enabling us to validate the use of our construction systems in seismic zones.

The calculation methods presented in our approvals comply with EUROCODES.

Although there are several possible implementations, is ITI preferable with wood-based concrete facades? If so, why? What type(s) of treatment are preferred for thermal bridges in ITI?

The use of TimberRoc wood-based concrete creates a wall with distributed insulation and inertia.

In ITI applications, the boards integrated into the slab nose panels help reduce thermal bridges. TimberRoc wood-based concrete also works well in ITE applications.

Can TIMBERROC® wood-based concrete be used to make beams?

No, wood-based concrete only comes in the form of prefabricated panels.

What are the usual wall and floor thicknesses for different construction principles?

- 24 or 30 cm for structural and load-bearing panels (CS2)

- 16 or 20 cm for self-supporting facade (FP2) or non-load-bearing facade (FP3)

- Between 25 and 40 cm for a floor (DS1)

Your CS2 construction principle has been validated by an ATEX case A, but this is time-limited... how long is it valid for? Do you intend to obtain other technical approvals in the medium and long term?

It is limited to 2 years, and will be followed by a technical opinion before it expires for load-bearing walls.

Does it work in the same way as reinforced concrete walls? Can the panels be made to work as a sail-beam?

No

What floor thickness is required for a slab with a 7 m span?

5 CM

For wood-based concrete separating walls, is a thickness of 20 cm sufficient between two apartments?

No, in general, we leave the separating walls in conventional concrete or we can study wood-based concrete walls of at least 24 cm with a lining for acoustic reasons.

How thick should the facade be in order to achieve the same performance as a 16 cm concrete shell + 12 cm polystyrene?

Thermal performance:

For a CS2 load-bearing wall: a 24 cm panel + 8 cm of GR32 glass wool

For a FP2/FP3 wall: a 16 cm panel + 10 cm of GR32 glass wool

How are the vertical/horizontal elements connected to each other?

For the CS2 principle: conventional reinforced concrete ties are cast on site at each vertical panel junction, in a similar way to block or brick masonry construction.

For FP2 and/or FP3: the panels are mechanically fastened by metal brackets to the reinforced concrete columns and slabs of the building structure.

Would it be possible to have a design guide for your wood-based concrete products with technical details?

You can already find an illustrated mini guide to CS2 load-bearing walls on our website, in the "Documentation" section.

What are the height limits for load-bearing wall construction? Non-bearing walls? What about the maximum span of your floors?

For load-bearing walls, we are limited to 3 superimposed levels of wood-based concrete panels (or 4 with the first floor).

This enables us to create buildings of up to 3 storeys or the last three levels of a 28m-high building. In non-load-bearing walls, we can go up to a maximum of R+10.

For floors, we can span up to 7m.

Do I need to protect the walls/slabs throughout the works? How long do walls need to dry on site before plastering?

TimberRoc wood-based concrete can absorb ambient humidity.

All you need to do is protect the wall heads from weather conditions. As for wall drying time, we recommend waiting a minimum of 3 to 6 months before plastering, depending on climatic conditions.

How thick, with insulation, is a load-bearing wall made of TimberRoc® wood-based concrete?

This depends on the climatic zone; for example, under the RE2020, in the Paris region (zone 1), a thickness of 24 cm is recommended for the wood-based concrete wall, with the addition of 16 cm of glass wool or 20 cm of wood wool.

Concerning the exterior rendering, is the substrate designed to receive a single-coat hydraulic rendering? With fiber-reinforced mesh at openings? and at vertical joints between elements? Or should the entire surface be treated?

Our product is rated RT3 for pull-out resistance, and we recommend OC1 or OC2 hydraulic binder coatings (mineral coatings).

Coating work must be carried out in compliance with NF DTU 26.1, and we recommend treating the entire surface or, at the very least, weatherstripping panel joints and singular points (as for "classic" masonry).

What are the possible seismic zones?

Zones 1 to 4 are classified as very low to medium seismicity.

What is the possible size of openings (doors, windows, etc.)?

It all depends on the construction principle. With CS2 (structural and load-bearing panels), we can design openings of up to 6m. FP2 and FP3 (self-supporting and non-supporting facades), on the other hand, allow openings of up to 2.4m.

Characteristics of TimberRoc® wood-based concrete

Why have you kept the word "concrete" to describe your product?

This is lightweight aggregate concrete of bio-sourced origin, containing no sand or gravel (exhaustible resources). These inert aggregates have been replaced by wood aggregates (renewable resources), bearing the "Bois de France" label. Our material contains 80% wood by volume, earning it the "Biosourced Product" label.

![]()

What are the main characteristics of TimberRoc® wood-based concrete, apart from its negative carbon footprint?

Is the exposure class of wood-based concrete identical to that of ready-mix concrete (with respect to aggressive, chlorinated environments, etc.)?

As the concrete is not reinforced, there is no problem of deterioration of the reinforcement.

Salt-air durability tests have been carried out and are conclusive.

What is the compressive strength of a TimberRoc® wood-based concrete wall?

Average strength is 4 MPa. Our material can take 23.6t/mL for 24cm thick panels and 29.5t/mL for 30cm thick panels, for a panel height of 3m.

With regard to the water vapor permeability of wood-based concrete, what is the water vapor diffusion resistance coefficient (μ) and the water vapor diffusion resistance (Sd value)?

Laboratory tests give a μ value close to 10 (wet cup method). Sd is calculated using the formula Sd = μ *e, for a 24 cm wall, giving Sd = 2.4.

What can you say about the thermal performance of a TIMBERROC® wood-based concrete wall?

Wood-based concrete offers distributed thermal insulation and thermal inertia properties (phase shifting/thermal damping):

High thermal phase shift:

- 17h on a 30 cm thick rough wall

- 14h on a 24 cm thick rough wall

Maximum thermal amortization :

- 96% for a 30 cm thick wall and

- 94% for a 24 cm thick wall.

- R=1.9 for a 30 cm thick wall

- R=1.5 for a 24 cm thick wall

- R = 1 for a 16 cm thick wall

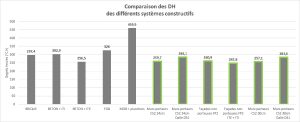

In the context of RE2020, we regularly hear that wood construction is hampered by a lack of inertia. Does TimberRoc wood-based concrete have the same problem?

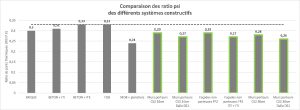

On the contrary, wood-based concrete has a very good thermal inertia, and the comparison with FOB or MOB is explicit on this diagram, which highlights the DH (source: SOLAB July 2022 study simulating the construction of a collective building).

Is wood-based concrete reinforced in the same way as reinforced concrete?

No

Does the use of TimberRoc® wood-based concrete, for facades only, allow us to comply with the linear psi limit?

Here's the answer in pictures: (source: SOLAB July 2022 study simulating the construction of a collective building).

What is the thermal resistance of TIMBERROC® wood-based concrete?

The thermal conductivity of concrete is λ = 0.16 W/(m.K).

The geometric shapes of wood-based concrete are classic, but is it possible to create curved walls or specific geometries?

No

What is the maximum wall height on one level?

3.30m slab to slab

Aren't PVs called into question when fire dampers are installed?

Our material has a fire rating of A2-s1-d0 (formerly M0), so we'd need to check that the PVs are valid for a material with such a rating.

What is the tested fire resistance?

This depends on the construction principles and the vertical load. TimberRoc wood-based concrete walls can have REI fire resistances of 60 to 120 min, while slabs can exceed 240 min.

Is TimberRoc® wood-based concrete sensitive to moisture, particularly frost and rain?

A wood-based concrete wall is always clad with cladding or plaster from the outside, so it's never untreated and therefore protected from the elements.

What is the heat capacity by mass (J/Kg.K) of wood-based concrete?

At 23°C: 1221 J/(Kg.K)

What about acoustics?

Feedback from users of wood-based concrete buildings is unanimous: "there's no resonance, it's very comfortable".

In fact, the Alpha_w reverberation coefficient of a wood-based concrete panel is 0.7, close to that of acoustic panels. The result is remarkable sound absorption.

The price

What are the estimated costs per m² veil/slab?

Between €180 and €220 per m² delivered and installed, depending on the thickness and construction principles chosen. This is an estimate; only our prefabrication partners and masons are able to give precise prices.

It is important to study the impact on the overall cost of the project, as many savings can be made:

- A lighter foundation!

Wood-based concrete weighs 3 times less than concrete, so foundations require less reinforcement

- A well-designed, eco-friendly building system

Most wood-based concrete projects do not require thermal breakers

- The key to energy savings

The thermal performance of wood-based concrete, in particular its phase shift, creates an inertia within the building that prevents overheating and/or air conditioning.

- Large quantities of biosourced materials without exploding costs

For all projects requiring a certain level of biobased materials, the price per kg of biobased materials is studied. The price of wood-based concrete is estimated at €4 per kg of biobased material, while the price of MOB is €12!*.

Not to mention that the presence of 80% wood by volume confers a unique carbon footprint, enabling savings to be made on complementary materials while reducing the overall carbon footprint.

*Source: Price research department of one of France's largest general contractors.

On the latest projects delivered, the extra cost of wood-based concrete on the overall cost was between 4% and 6% compared with the same project in concrete or brick.

Marketing

Who are our prefabrication partners?

We currently have two prefabrication partners:

- Spurgin Leonhart

http://www.spurgin.fr/produits/premur/ - R-Technologies (Cheminal Group)

- Capremib

Further partnerships will be announced shortly to complete the national network.