Our key strenghts

of French wood by volume

The wood aggregates used in the cement matrix are sourced from French “wood for pulp” — a co-product of sustainable forest management. This local sourcing qualifies them for the “Bois de France” certification.

Carbon footprint

The carbon storage generated by the wood aggregates is so significant — and lasts throughout the entire lifespan of the material — that some of our construction solutions achieve a negative carbon balance (as demonstrated by five verified EPDs available on the INIES database). Whether the balance is highly negative or slightly positive, the key takeaway is that it enables compliance with the 2031 thresholds of the RE2020 regulation.

Off site construction

All our solutions — TimberROC® and ParkROC® — are based on off-site construction. Prefabricated elements significantly reduce installation time on site, minimise the risk of workplace accidents, and ensure cleaner, more efficient worksites with much lower water consumption.

New construction / Walls and floor slabs

Load-bearing walls up to four storeys, infill façades up to ten storeys, and off-site manufactured floor slabs enable the construction of all types of low-carbon, bio-based buildings while ensuring comfort and safety for occupants.

Thermal mass and time lag

17-hour thermal time lag and 98% damping for a 30 cm load-bearing wall.

Guaranteed summer comfort

Maintains indoor temperatures below 26 °C even after several consecutive heatwave days. Client feedback and performance reports available.

Acoustic absorption

An αw coefficient of 0.70 drastically reduces sound reverberation.

High fire resistance

REI 60 to 120 min – Class A2-s1-d0 for walls, and REI 240 min for floor slabs.

Outdoor spaces / Car parks and pedestrian walkways

ParkROC® is a wood-based concrete permeable slab that halves the carbon footprint of a conventional surface, absorbs up to 120 L/min/m², and helps reduce urban heat islands. Ideal for pedestrian pathways, light vehicle car parks, and sustainable landscape developments.

Frost-resistant / Freeze–thaw cycles

No chipping or cracking after 30 cycles + de-icing salts

Stormwater management

> Effective stormwater management, with drainage rates exceeding 120 L/min/m² and a retention capacity of 40 L/m².

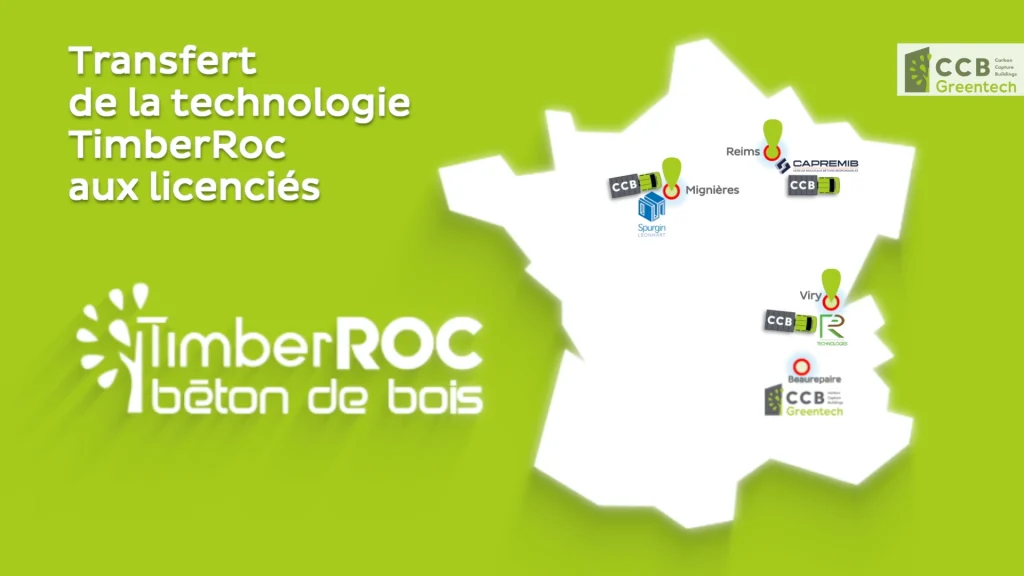

A shared expertise

A network of prefabrication partners close to every project

We transform wood into aggregates.

Our licensed TimberROC® partners, specialists in off-site construction, carry out the prefabrication of structural systems for faster, more controlled, and low-carbon projects.

Thanks to them, TimberROC® technology is deployed across France, as close as possible to each construction site — reducing transport distances and ensuring high-quality implementation. They support project teams from the design stage, through an integrated design office dedicated to wood-based concrete, right up to the delivery of prefabricated elements on site. Training for installation teams can also be provided.

Spurgin

Plant dedicated to wood-based concrete in Mignières (Eure-et-Loir), near Chartres.

R-Technologies

(Groupe Cheminal)

Prefabrication plant located in Viry (Haute-Savoie, 74), in the French Alps.

Capremib

The most recent partner to join the adventure in 2025, with a plant located near Reims (Marne).

They have already delivered projects built with wood-based concrete!

The first multi-family building in France made of wood-based concrete was completed in 2022 in Bonson (Loire, 42).

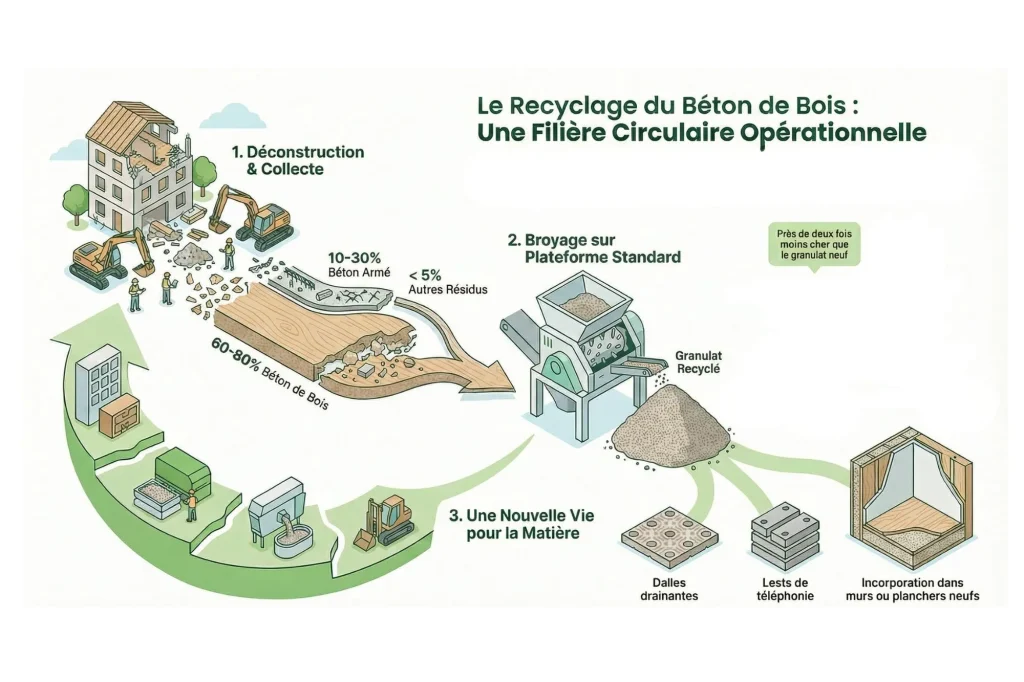

WOOD CONCRETE RECYCLING: the circle is complete!

Recycling wood-based concrete is a key issue for sustainable construction and the circular economy. TimberRoc wood-based concrete is a lightweight cementitious concrete incorporating wood aggregates. As such, its end-of-life cycle fits directly into the existing concrete recycling chain, without the need to create a specific channel.

Operations carried out since 2022 have demonstrated real and operational recyclability, compatible with the requirements of environmental certifications.

End-of-life integrated into the concrete recycling chain

When buildings are deconstructed, wood-based concrete panels are processed in the same way as conventional concrete. Once the secondary elements have been stripped, the shell is deconstructed, then the materials are collected and sent to standard concrete platforms. Deposits resulting from deconstruction are mainly composed of wood-based concrete, supplemented by reinforced concrete and mineral residues in controlled proportions. These materials are then crushed using conventional concrete crushers, with or without screening depending on the intended use. This integration into an existing supply chain guarantees the availability, traceability and reproducibility of wood-based concrete recycling.

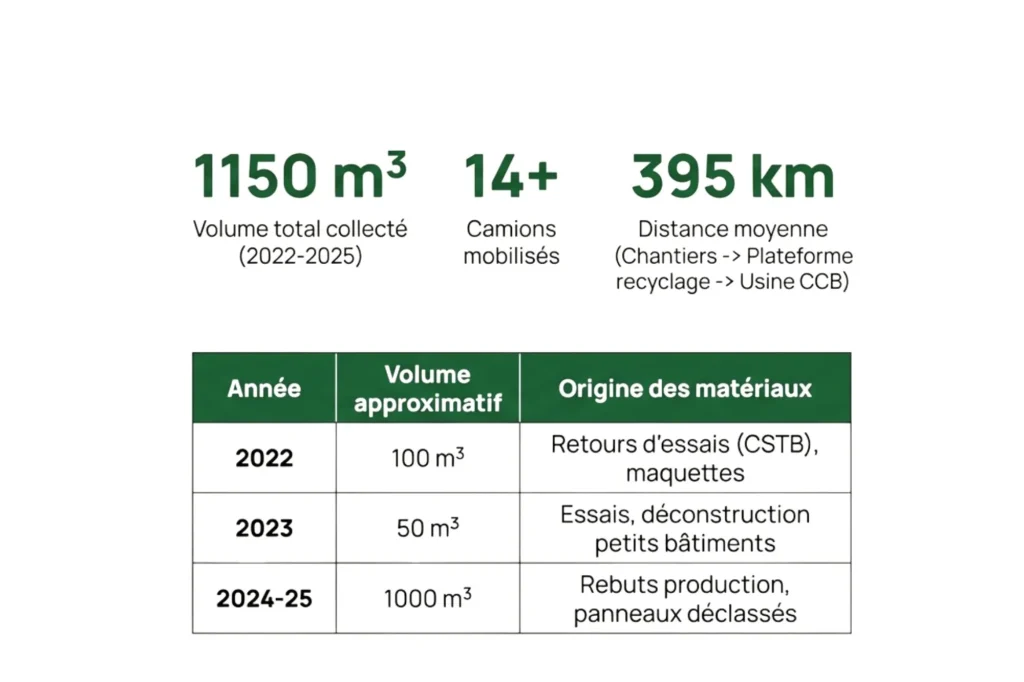

Recyclability demonstrated by field operations

Between 2022 and 2025, CCB Greentech carried out several collection and recycling campaigns involving panels from test returns, production scraps and deconstructed buildings. Over 1,000 m³ of wood-based concrete were collected and recycled under real-life site conditions. The aggregates produced by crushing have an average density of around 550 kg/m³. They are checked for grain size, density and moisture content to ensure their compatibility with new applications. These results confirm the operational recyclability of wood-based concrete, even after ageing and combination with other building materials.

Reusing recycled aggregates in new applications

Recycled aggregates from wood-based concrete are now being reintegrated into various applications. In particular, they are used in draining slabs, ballast elements and, in controlled proportions, in new wood-based concrete elements such as walls and floors. This reintegration of materials transforms the end-of-life of buildings into a resource, while relying on existing industrial infrastructures. It represents a concrete lever for the circular economy applied to construction materials.

TimberRoc® wood-based concrete is a recyclable material at the end of a building’s life. Its recycling chain, integrated with traditional concrete recycling, is now operational, documented and proven by field feedback. This approach makes it possible to meet current technical and environmental requirements, while providing concrete guarantees for end-of-life management.

Do you have wood-based concrete products to recycle?

CCB Greentech provides an operational recycling channel for your end-of-life wood-based concrete panels or elements.

Conditions for accepting materials:

– Products must be free of all insulation, cladding, film, wood inserts or metal fasteners

– Maximum dimensions: 240 cm x 200 cm. If your elements exceed these dimensions, please fragment them before removal

– Elements may contain reinforced concrete and raw wood residues.

Send your project requests or questions to: contact@ccbgreentech.com

Your low-carbon project starts here

Contact us today — you’ll receive a response within 48 hours to discuss your sustainable construction or landscaping needs.